Difference between revisions of "Factors that influence beer fermentation"

(→Sources) |

(→Conclusion) |

||

| (14 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

=Introduction= | =Introduction= | ||

| + | |||

| + | This simulation focuses on addressing factors that have an effect on beer fermentation and influence the alcohol percentage in the final product. It should suit the brewery makers in the food industry to better evaluate beer-making conditions to make preferred outcomes of alcohol levels. This simulation was developed as part of the project for the 4IT496 Simulation of Systems class. | ||

=Problem definition= | =Problem definition= | ||

| + | |||

| + | Due to the complex interactions between internal and external variables, brewers continue to face crucial challenges in accurately regulating the alcohol content of beer fermentation. The final alcohol percentage is directly influenced by variables like sugar concentration, yeast type selection, and temperature fluctuations. This simulation attempts to give brewers a comprehensive platform to experiment with different scenarios to optimize their brewing procedures. This model aims to equip brewers with practical insights so they may make well-informed decisions for consistent and ideal alcohol levels by addressing the complex dynamics of beer fermentation. | ||

=Method= | =Method= | ||

| + | |||

| + | The Vensim PLE modeling software was chosen for the solution of the above-described case. | ||

=Model= | =Model= | ||

| + | |||

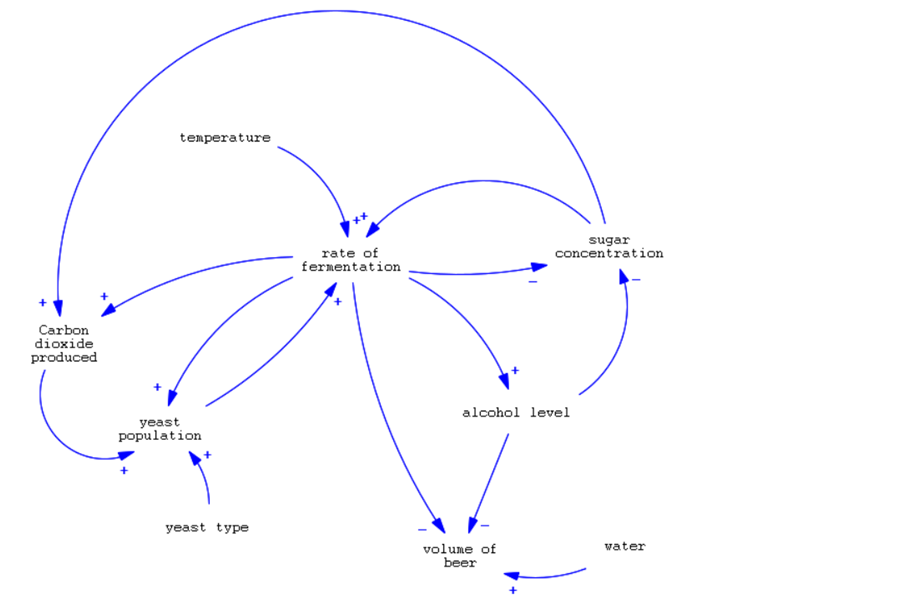

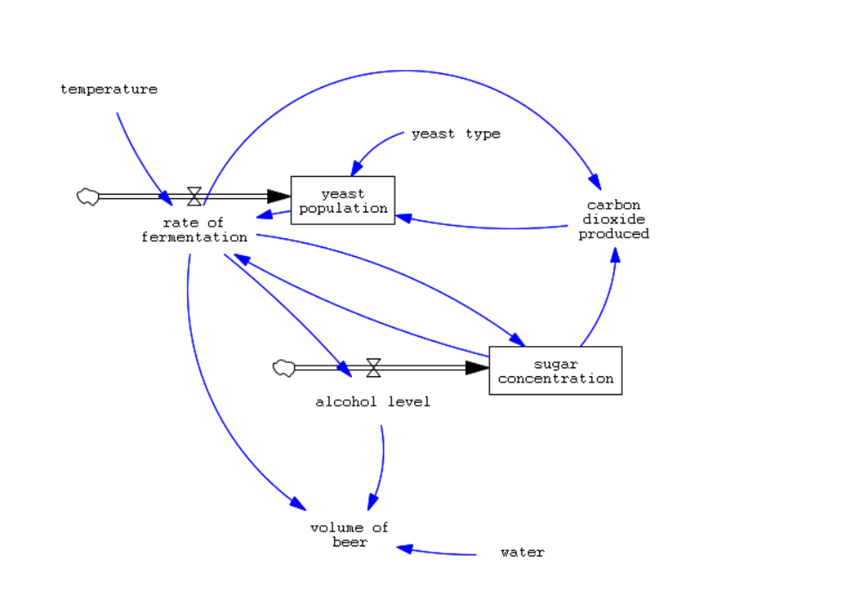

| + | [[File:Beer11.png]] | ||

| + | [[File:Beer22.png]] | ||

| + | |||

| + | =Variables= | ||

| + | |||

| + | ===Temperature=== | ||

| + | |||

| + | Represents the temperature of the fermentation process. | ||

| + | |||

| + | ===Rate of Fermentation=== | ||

| + | |||

| + | Represents the speed at which fermentation is occurring. | ||

| + | |||

| + | ===Yeast population=== | ||

| + | |||

| + | Represents the quantity of yeast cells involved in fermentation. | ||

| + | |||

| + | ===Yeast type=== | ||

| + | |||

| + | Represents the type or strain of yeast used in fermentation. | ||

| + | |||

| + | ===Carbon Dioxide Produced=== | ||

| + | |||

| + | Represents the production of carbon dioxide as a byproduct of fermentation. | ||

| + | |||

| + | ===Sugar Concentration=== | ||

| + | |||

| + | Represents the amount of sugars available for fermentation. | ||

| + | |||

| + | ===Alcohol Level=== | ||

| + | |||

| + | Represents the concentration of alcohol in the beer. | ||

| + | |||

| + | ===Volume of Beer=== | ||

| + | |||

| + | Represents the quantity of beer in the fermentation process. | ||

| + | |||

| + | ===Water=== | ||

| + | |||

| + | Represents the amount of water involved in the fermentation process. | ||

=Results= | =Results= | ||

| + | |||

| + | Unfortunately, there were no concrete outcomes from the simulation. Despite attempts to investigate the complex dynamics of beer fermentation and model the different elements determining alcohol content, the results lacked practical significance and were inconclusive. The complexity of beer fermentation may call for a more sophisticated method, thus it's critical to recognize the limitations of the current model. Even though the simulation failed to provide conclusive results, this outcome offers a chance for exploration and learning about the complex interactions that occur during the brewing process. | ||

=Conclusion= | =Conclusion= | ||

| + | |||

| + | The simulation aimed to understand the dynamics of beer fermentation, examining variables such as temperature, yeast type, and sugar concentration. Regretfully, the findings lacked clarity and couldn't provide the expected insights for brewing process optimization. This demonstrates the complex nature of beer fermentation and indicates that the simulation model has to be further improved. | ||

=Code= | =Code= | ||

| + | *Casual Loop: | ||

| + | [[File:Beer.mdl]] | ||

| + | *Stock and Flow: | ||

| + | [[File:Beer2.mdl]] | ||

=Sources= | =Sources= | ||

Latest revision as of 00:35, 21 January 2024

Author: Adéla Dobešová, Doba00 (talk) 22:04, 20 January 2024 (CET)

Tool: Vensim

Contents

Introduction

This simulation focuses on addressing factors that have an effect on beer fermentation and influence the alcohol percentage in the final product. It should suit the brewery makers in the food industry to better evaluate beer-making conditions to make preferred outcomes of alcohol levels. This simulation was developed as part of the project for the 4IT496 Simulation of Systems class.

Problem definition

Due to the complex interactions between internal and external variables, brewers continue to face crucial challenges in accurately regulating the alcohol content of beer fermentation. The final alcohol percentage is directly influenced by variables like sugar concentration, yeast type selection, and temperature fluctuations. This simulation attempts to give brewers a comprehensive platform to experiment with different scenarios to optimize their brewing procedures. This model aims to equip brewers with practical insights so they may make well-informed decisions for consistent and ideal alcohol levels by addressing the complex dynamics of beer fermentation.

Method

The Vensim PLE modeling software was chosen for the solution of the above-described case.

Model

Variables

Temperature

Represents the temperature of the fermentation process.

Rate of Fermentation

Represents the speed at which fermentation is occurring.

Yeast population

Represents the quantity of yeast cells involved in fermentation.

Yeast type

Represents the type or strain of yeast used in fermentation.

Carbon Dioxide Produced

Represents the production of carbon dioxide as a byproduct of fermentation.

Sugar Concentration

Represents the amount of sugars available for fermentation.

Alcohol Level

Represents the concentration of alcohol in the beer.

Volume of Beer

Represents the quantity of beer in the fermentation process.

Water

Represents the amount of water involved in the fermentation process.

Results

Unfortunately, there were no concrete outcomes from the simulation. Despite attempts to investigate the complex dynamics of beer fermentation and model the different elements determining alcohol content, the results lacked practical significance and were inconclusive. The complexity of beer fermentation may call for a more sophisticated method, thus it's critical to recognize the limitations of the current model. Even though the simulation failed to provide conclusive results, this outcome offers a chance for exploration and learning about the complex interactions that occur during the brewing process.

Conclusion

The simulation aimed to understand the dynamics of beer fermentation, examining variables such as temperature, yeast type, and sugar concentration. Regretfully, the findings lacked clarity and couldn't provide the expected insights for brewing process optimization. This demonstrates the complex nature of beer fermentation and indicates that the simulation model has to be further improved.

Code

- Casual Loop:

- Stock and Flow:

Sources

- https://www.phind.com/search?cache=uu8fcm0sqdc1fyznvi0o0rhx&fbclid=IwAR30Y-m8maeJI3WFcW-fLvqTlRov_63mfnCGPxC9RiANZQbkQaYNO8MDl0M

- https://science.howstuffworks.com/innovation/edible-innovations/beer4.htm

- https://www.researchgate.net/publication/284725490_Biochemistry_of_beer_fermentation

- chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/http://ucitelchemie.upol.cz/materialy/vkpch/vyroba_piva_text_pro_ucitele.pdf

- https://grainfather.com/beer-fermentation-process/#:~:text=Typically%20the%20cooler%20the%20temperature,unwanted%20attributes%20in%20the%20beer.

- Mosher, M., & Trantham, K. (2021). Brewing Science: a Multidisciplinary approach. In Springer eBooks. https://doi.org/10.1007/978-3-030-73419-0